Crushing and screening machines get North American premiere

14 March 2023

Three new mobile crushing and screening equipment models from manufacturer Kleemann have been presented to the North American construction industry for the first time, making their regional debut at the ConExpo 2023 trade fair in Las Vegas.

The MSS 802i EVO Mobiscreen. (PHOTO: Kleemann)

The MSS 802i EVO Mobiscreen. (PHOTO: Kleemann)

Among the line-up is Kleemann’s Mobiscreen MSS 802i EVO mobile screener for coarse feed materials up to 500 mm in size. The double-deck screening unit can classify up to three fractions and has a feed capacity range from 200 to 500 t/h.

Kleemann says, “The large range of screen surfaces and simple setting of screen parameters enable easy adaptation of the MSS 802(i) EVO to new application conditions. If a fine final product is to be screened from extremely coarse feed material, the plant can be quickly converted from three to two final grain sizes.”

It also features a feed hopper with a rear wall that can be folded to three different heights for optimal material transport from the loading machine, and includes an integrated spray system and water pump for to reduce dust.

Designed for maximum flexibility, the MSS 802i EVO features a Dual Power System that allows the unit to be powered by either its diesel engine or an external power supply. A fast set-up system and an automatic start function are also incorporated, with the 38.9-t machine also offering transport dimensions of 3.4 m in height, 15.8 m in length and just 3 m in width.

Alongside the MSS 802i EVO, Kleemann also premiered its Mobicat MC 110i EVO2 jaw crusher and the Mobicone MCO 90i EVO2 cone crusher.

The Mobicat MC 110i EVO2 jaw crusher can handle up to 400 t/h of feed material, is fitted with a crusher unblocking system and has a maximum transport weight of 49 t. Meanwhile the 45.6-t Mobicone 90i EV2 cone crusher offers a feed capacity of up to 270 t/h, and can be used as a secondary or tertiary crusher.

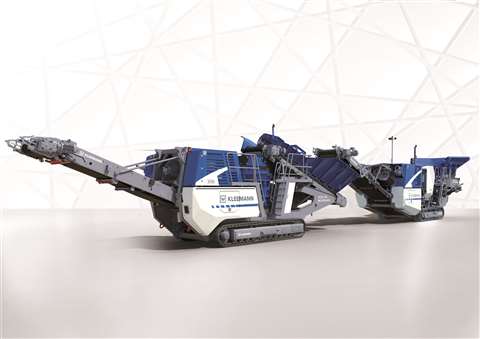

The MCO 90i EVO cone crusher and the MC 110i EVO2 jaw crusher. (PHOTO: Kleemann)

The MCO 90i EVO cone crusher and the MC 110i EVO2 jaw crusher. (PHOTO: Kleemann)

Designed for natural stone and recycling applications, both models are fitted with a diesel engine from Scania and include intelligent overload systems.

They are also said to offer easy operation thanks to Klemmann’s SPECTIVE operating concept and the newly-available SPECTIVE CONNECT.

The digital technology, which machine operators can use via their smart phone, provides live machine data and camera images of the machine. This allows users to monitor speed, consumption value, productivity and fault messages, from inside the cab of the loading machine.

“Apart from the intuitive touch panel and different radio remote controls, the digital application SPECTIVE CONNECT, above all, supports the work site digitalization,” said Kleemann.

“All relevant process information and reporting are now displayed on your smartphone without having to leave the feeding device.”

SPECTIVE and SPECTIVE CONNECT allow users to monitor Kleemann’s EVO2 crushers from the cab of the loading machine. (IMAGE: Kleemann)

SPECTIVE and SPECTIVE CONNECT allow users to monitor Kleemann’s EVO2 crushers from the cab of the loading machine. (IMAGE: Kleemann)

CONNECT WITH THE TEAM