Keestrack targets zero emissions

27 October 2022

Belgian crushing and screening equipment manufacturer Keestrack is exhibiting a range of electric machines under its “Join the e-volution” banner, after a busy period of product development in the past two years.

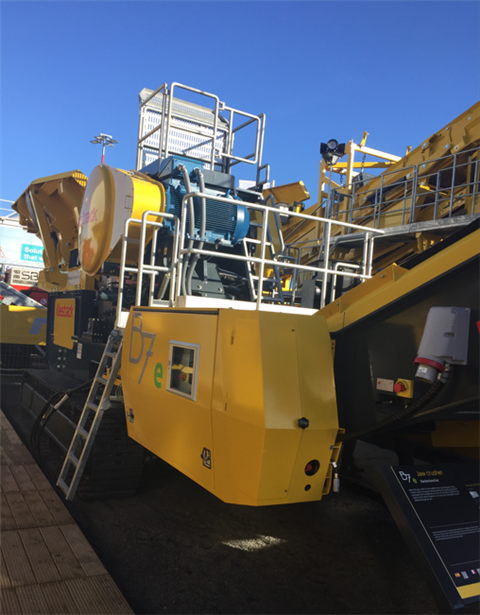

The B7e zero drive jaw crusher on show at Bauma. (Photo: D&Ri magazine)

The B7e zero drive jaw crusher on show at Bauma. (Photo: D&Ri magazine)

Marketing manager Marcel Kerkhofs said: “We have a strong reputation for cost-effective equipment with a relentless search for the best performance at the lowest cost per produced ton, using the best drive system possible.

“Today this means going electric.”

Keestrack introduced electric drives in 2012 by the e-drive; electric plug-in with onboard diesel/gen-set in case there is no electric plug-in available. The e-driven machines evolved into equipment with a drop-off engine or genset unit which could be placed next to the equipment, in less dusty surroundings, or on the frame of the machine.

With its zero-drive systems, there are no combustion engines on board, as electric motors drive most of the mobile crushing and screening equipment and power some necessary hydraulics systems.

The B7e zero drive jaw crusher on show at Bauma. (Photo: D&Ri magazine)

The B7e zero drive jaw crusher on show at Bauma. (Photo: D&Ri magazine)

Zero-drive options developed by Keestrack include cone crushers, impact crushers, scalper screens and jaw crushers.

“At this point electric drive systems are the greenest and most effective options on the market, as they are more efficient than conventional hydraulic systems,” said Keestrack group president Kees Hoogendoorn.

“But it also makes the end-user less dependent on a specific engine supplier.”

CONNECT WITH THE TEAM