Polar runway project for Sandvik

09 May 2023

Three Sandvik mobile crushers and screens have been deployed in the Antarctic, as part of the United Kingdom’s £300 million (US$378 million) Antarctic Infrastructure Modernization Programme (AIMP) for the British Antarctic Survey (BAS).

The QH332 hydrocone crusher and QA335 Doublescreen at the Rothera Research Centre site in Antarctica. (PHOTO: Sandvik/BAM)

The QH332 hydrocone crusher and QA335 Doublescreen at the Rothera Research Centre site in Antarctica. (PHOTO: Sandvik/BAM)

A Sandvik QH332 Hydrocone crusher and a QA335 Doublescreen were ordered by contractor BAM Ritchies for a runway resurfacing project at the Rothera Research Station, where modernisation works and the construction of a new science and operations facility - known as the Discovery Building - are underway.

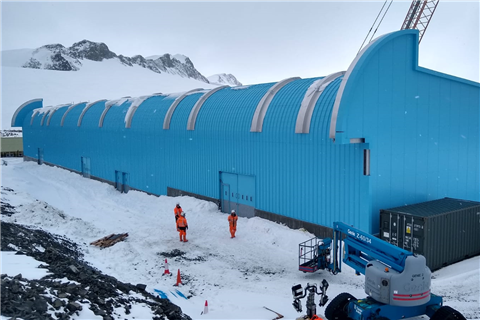

The resurfaced runway will serve the Rothera Research Centre, and its new research facility, the Discovery Building (pictured). (Image: Christopher Robery Lloyd)

The resurfaced runway will serve the Rothera Research Centre, and its new research facility, the Discovery Building (pictured). (Image: Christopher Robery Lloyd)

“BAM were in need of a processing train to crush and screen the abrasive granodiorite material so it could be recycled and reused for construction purposes at the research station.”

The Hydrocone crusher and the Doublescreen joined a previously delivered QH341 jaw crusher at the polar site, where temperatures rarely get above freezing.

“Living and working in the Antarctic is no mean feat and with temperatures ranging from 5°C to -40°C, it poses many environmental challenges,” said Sandvik. The company fitted each of the mobile units, which weigh between 26.5 and 50 t, with an arctic package.

Sandvik added that “For this particular application and job at hand, a Sandvik QH332 Hydrocone crusher and QA335 Doublescreen were selected due to their versatility and performance capacity.

The QH332 hydrocone crusher at the Rothera Research Centre site. (PHOTO: Sandvik/BAM)

The QH332 hydrocone crusher at the Rothera Research Centre site. (PHOTO: Sandvik/BAM)

The QH332 crusher and the QA335 Doublescreen are being used to crush the runway’s existing surface material down to make resurfacing material for an 800m unpaved gravel runway.

Sub 80mm feed already produced by the QJ341 jaw crusher is also being processed to produce surface course fractions of 0 to 16 mm, base course fractions of 0 to 25 mm, levelling course fractions measuring 0 to 75mm and sub-base material of less than 100 mm.

Harry McMullan, BAM Ritchies’ quarry manager for the project, said: “The cone crushers have a wide choice of set-up with different concave and mantle configurations plus different throws, which allows the machine to be adjusted and configured to a wide range of products.”

CONNECT WITH THE TEAM